news

read more

Stand with Nature.

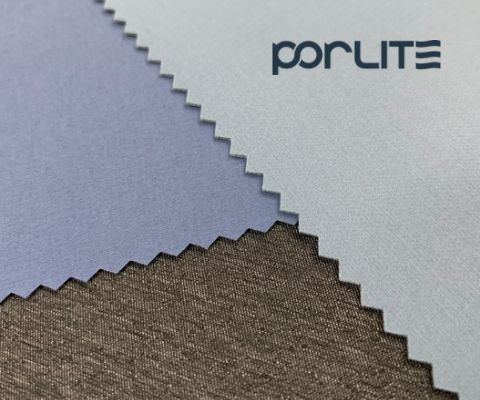

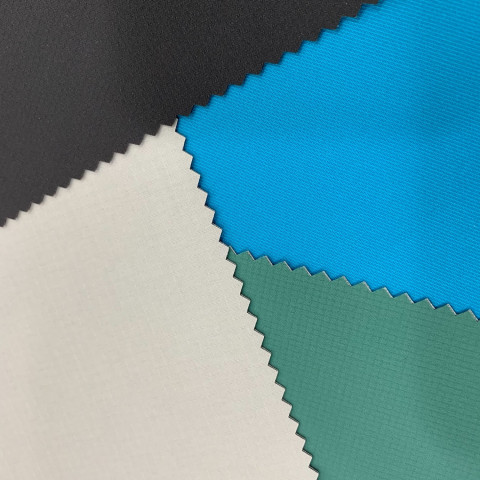

When you choose Porlite, not only do you choose the color and comfort of the fabric, you demonstrate your commitment to the environment and a connection with nature.

When you choose Porlite, not only do you choose the color and comfort of the fabric, you demonstrate your commitment to the environment and a connection with nature.

Products

About us

Hwafune Is One Of Taiwan’s Leading Manufacturers Of Innovative And Functional Fabrics. We Are Specialised In Functional Synthetic Fabric With Coating And Lamination As 2L, 3L, 4L, 5L In Hydrophilic & Microporous And Compound Finishing.