In the context of the current global economic landscape, the textile industry faces complex procurement challenges. Factors such as price volatility, supply chain disruptions, quality assurance challenges, and regulatory compliance requirements significantly affect a company's operational efficiency and financial stability.

Time Value: The Accumulation of Delay Costs

In the procurement process, time management is a critical implicit cost. Every delay results in the accumulation of costs, lost opportunities, and unmet customer demand. The loss of time is often more destructive than the loss of money, as it directly affects a company's competitive advantage and market opportunities—opportunities that, once missed, cannot be regained. These delays can disrupt production processes or deliveries. As these delays accumulate, the company will face a decline in sales revenue, a gradual weakening of competitiveness, and a long-term negative impact on growth potential. For example, Forever 21 experienced this when its supply chain coordination was inadequate, causing it to miss the peak sales season for trendy apparel. This led to a decline in revenue and brand competitiveness, ultimately forcing them to file for bankruptcy, close at least 200 stores in the U.S., and lose market share.

Implicit Costs: The Intangible Burden on Businesses

In addition to time value, implicit costs are another critical factor often overlooked in the procurement process. These implicit costs are difficult to quantify, but their impact on businesses is evident. These costs include, but are not limited to

• Inventory management issues : Excessive inventory ties up funds and increases storage costs, while insufficient inventory can lead to stockouts, failing to meet market demand.

• Quality control problems : Procuring low-quality raw materials can result in rework or scrap during the production process, leading to additional costs.

• Profit decline risks : Due to poor inventory management, businesses may be forced to sell at discounted prices or incur additional channel costs, further eroding profit margins.

• Legal and compliance risks : Failure to comply with local or international environmental and regulatory standards can lead to fines or lawsuits, further increasing financial burdens.

• Supply chain risks : Unstable suppliers may cause delivery delays, affecting production and marketing plans.

The textile industry faces growing procurement challenges, but these challenges also present an opportunity for transformation. By addressing time value and implicit costs, businesses can secure long-term growth and stability.

“ The time for change is now! Don’t let procurement challenges hold you back—take control with Porlite — your key to sustainable growth and efficiency.”

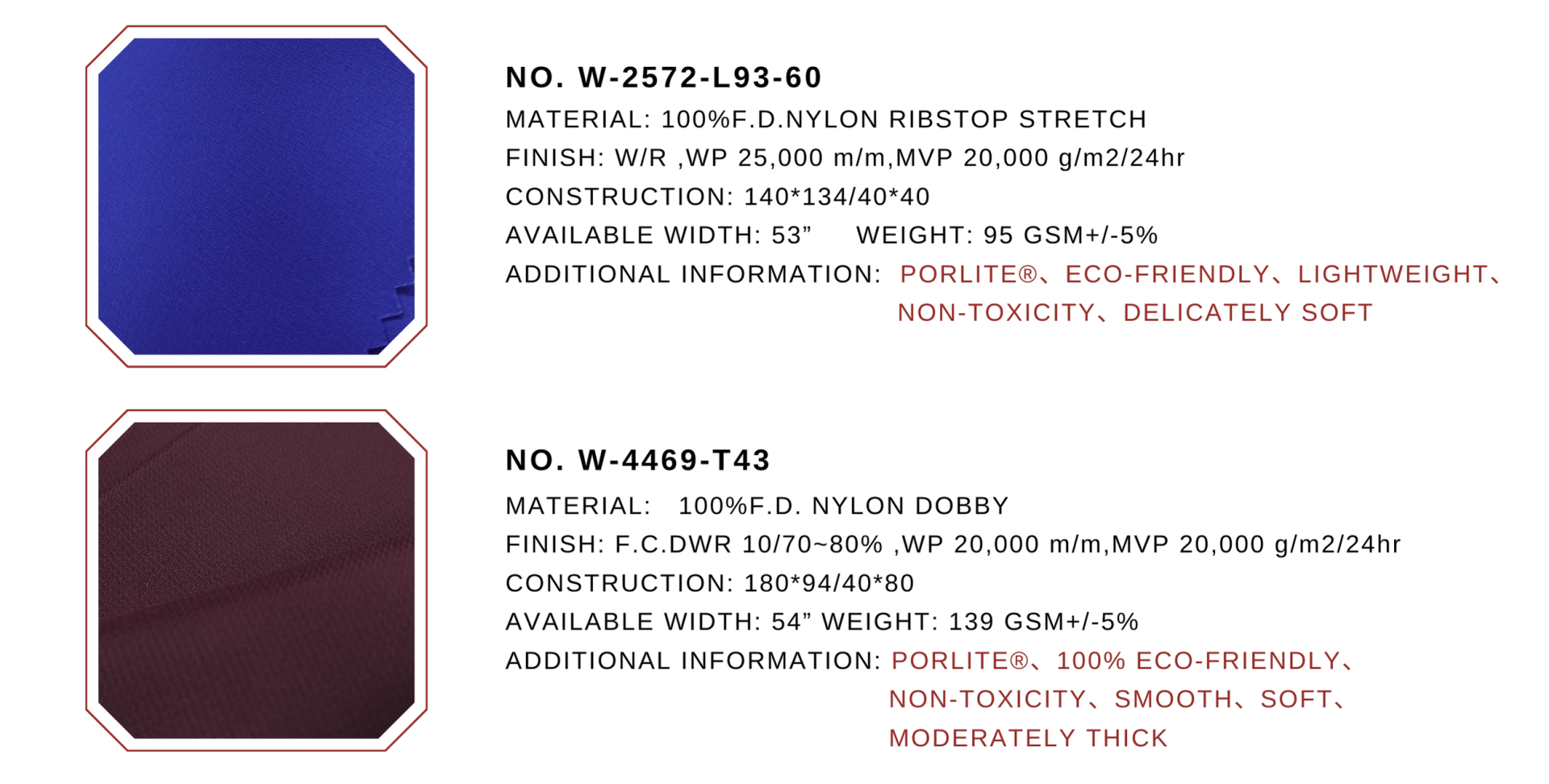

Fabric Recommendations