Have you ever encountered this situation: during the garment manufacturing process, after cutting, sewing, and washing, you find that the sleeves are uneven in length, or the seams have deformed due to shrinkage? When shrinkage control is unstable, these issues arise, disrupting the production process and incurring unnecessary additional costs.

As a garment manufacturer or brand owner, are you struggling with how to effectively control shrinkage and prevent such production problems? If so, we are here to help you solve this issue. Shrinkage refers to the dimensional changes that occur in fabric when exposed to heat and moisture. This issue is crucial for every apparel brand's production process. However, not all fabrics from brands on the market can easily control shrinkage, which becomes a significant challenge for many brands during production.

Formation & Control of Washing Shrinkage

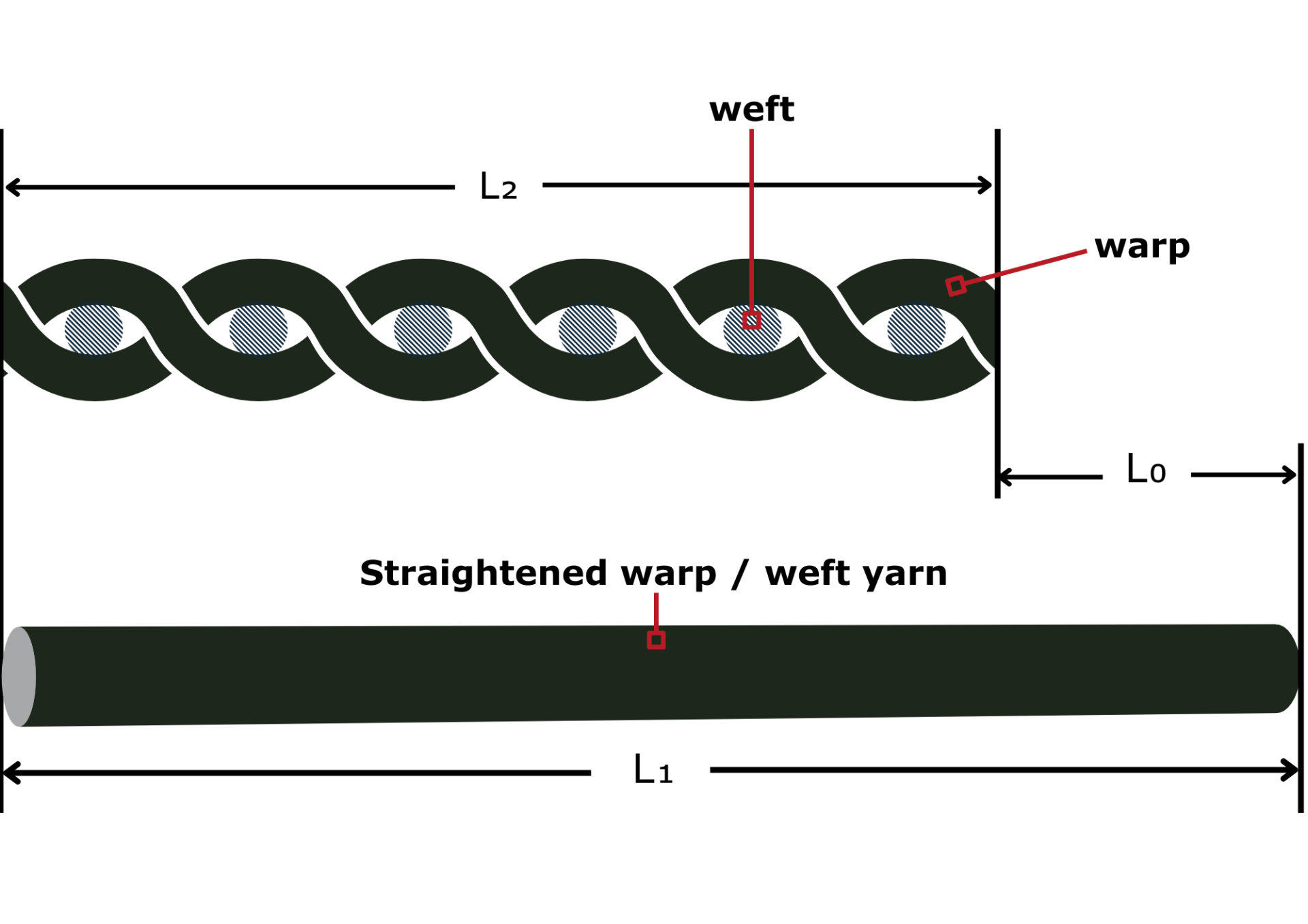

Shrinkage occurs due to the deformation of yarns during the weaving process. Yarns are initially linear structures, and before weaving, both the warp and weft yarns are held under tension in a straight alignment. As the weaving process progresses, the interlacing of the warp and weft yarns causes them to transition from a straight to a wavy, bent form, which shortens their length and forms the fabric.

This phenomenon, known as weaving shrinkage, is primarily driven by the bending of the yarns. The extent of shrinkage is directly influenced by the frequency of interlacing and the amplitude of the bending waves. Under normal usage conditions, synthetic fibers and yarns blended with synthetic fibers typically have lower shrinkage rates, such as polyester and nylon.

Next are linen, followed by cotton, which tends to shrink when washed with hot water and dried. The fibers with the worst shrinkage are rayon and viscose. Additionally, fabrics containing elastic fibers generally experience higher shrinkage, and wool is also more prone to shrinkage, which is why wool garments often recommend dry cleaning. Moreover, the fabric's production process— including weaving, dyeing, and finishing-process — significantly affects shrinkage.

Woven fabrics typically have lower shrinkage compared to knitted fabrics, and the tension applied during production also influences shrinkage after washing and drying.

Precision Control: Tailored to Every Percentage

At HwaFune, we understand the importance of shrinkage control in both garment production and garment manufacturing. Therefore, we have established strict quality control standards for shrinkage. For example, we control the shrinkage of non-spandex fabrics ± 3%, while spandex fabrics and our popular product Porlite (PP) membrane are maintained at ± 5%. Of course, if you have any specific requirements, we welcome you to contact HwaFune's expert team for further discussions and custom development, working together to create the next competitive, market-leading product.

Fabric Shrinkage and Procedure of Shrinkage Test - Textile Learner

Fabric Recommendations