news

2021 / 06 / 21

Bio Nylon| Hwa Fune eco series.

In the 21st century, consumers are increasingly demanding products that reflect their more sustainable values and lifestyles. Chemistry is giving way to synthetic biology, and engineered organisms—using the same kind of fermentation we use to make wine, bread, or kombucha—can now make the chemical building blocks for shoes, clothes, and carpets.

| *Castor oil Castor oil, derived from the seeds of the plant Ricinus communis, forms the basis of sebacic acid, which is the product’s renewable raw material content. Many manufacturers use castor oil to make biomass nylon. While maintaining the quality of nylon, it can also reduce fossil fuels and carbon emissions. |

|

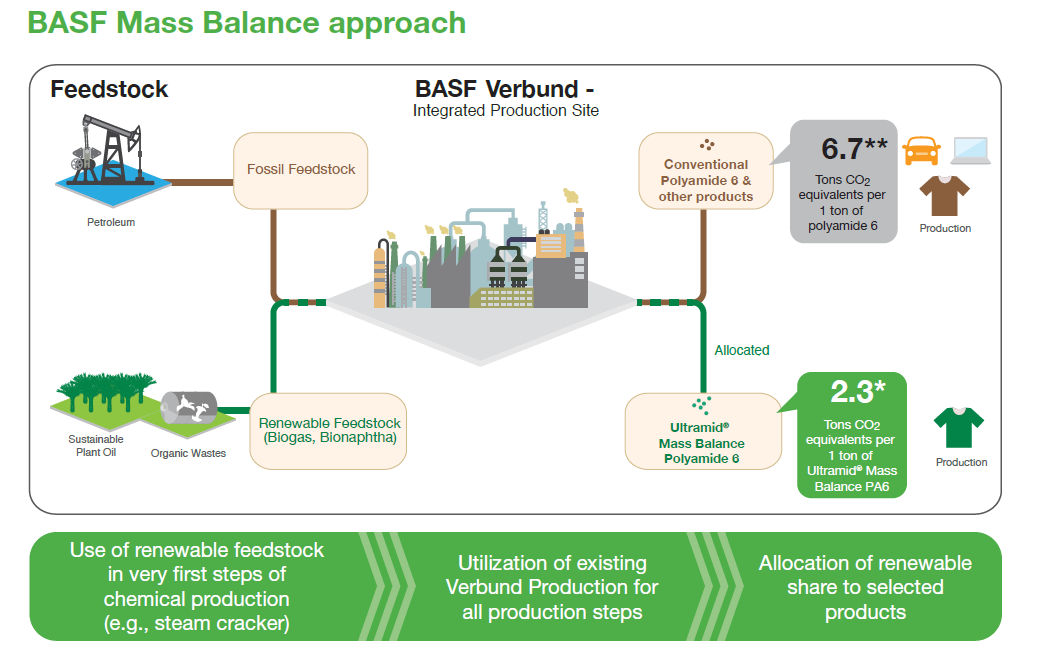

BASF has developed a groundbreaking approach to derive products from renewable raw materials: Certified renewable feedstock is used to replace fossil resources at the beginning of the production process and is then allocated to sales products in the respective quantities.

|

|

|

W-4983-L07G •57%Bio Nylon 43%Nylon6.6 Stretch(2-way)

•F.C.LDWR30/70-80%, WP 20,000m/m, MVP 20,000g/m2/24hr

•Weight: 152GSM±5

•DUPON B20W SUSTERA/ Ultramid®(BASF)

|

|

CONTACT US for more information or products.

Information source:

BASF<Biomass Balance by BASF: Building a sustainable future>